No matter if you are a professional craftsman or a DIYer, most likely than not, you’ve a handheld saw for some jobs and definitely it was not an easy task requiring good skill, pretty much effort, and time. With a table saw, heavy-duty wood cutting jobs and large-scale woodworking projects will be as easy and hassle-free as never before. This machine delivers more power, precision, and functionality for you to achieve professional-grade cutting results in no time.

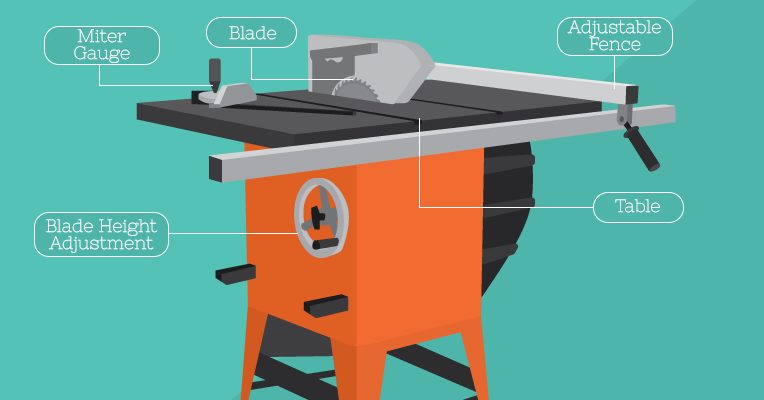

Being one of the most used woodworking equipment, a table saw commonly consists of a circular saw blade installed on a kind of table or stand and a forceful electric motor. Many modern models feature a dust collector to be connected to a vacuum cleaner for mess-free unit operation. Normally, all table saws have the same basic parts, however, the unit design might somewhat differ depending on the table saw type.

In general, there are two major types of table saws. These are portable and stationary machines. Portable models in its turn fall into maximum compact and lightweight bench top units designed for light-duty works and home use and more robust jobsite machines featuring wheels and folding stands and meant for some occasional on-site cutting works. All stationary models are bulkier and heavier than portable ones, yet they are much more powerful and accurate as well. Stationary tables saws are divided into contractor machines distinguished by high-power induction motors and big ragged cast iron tables and designed mostly for professional use and cabinet saws which are the biggest and the most powerful of all models and feature large and beefy parts ensuring less vibration and the ultimate precision during work.

Personal safety could never be neglected when working with any cutting tools. Featuring rather a big and ultra-sharp blade rotating at high speeds, any table saw is related to a high risk of cuts and injuries. Hence, before you start mastering table saw cutting techniques or proceed with tailoring your skills to a more advanced proficiency level, take all the necessary precautions to work maximum safely and reduce the possibility of body injuries to the minimum.

- The very first thing to do is to read an instruction manual to install and use your table saw in a proper way.

- Always wear proper safety equipment such as protective clothing, safety goggles, and ear protection. Loose clothing and hanging jewelry are potential hazards to avoid during work.

- Maintain the working area clean and free from sawdust, wooden chips, and stock when cutting.

- Make sure all unit safety features (such as a blade guard, riving knife, and anti-kickback protection) are operable and properly adjusted.

- Take a comfortable and well-balanced standing position and avoid some awkward and abrupt movements when working.

- Never start the unit with the blade engaged, avoid reaching over or behind the blade when making some adjustments, and always unplug the machine when changing the blades.

- Check a workpiece for any foreign objects such as nails and screws that can cause the blade malfunction and injuries.

- Avoid free-hand cuts and use special inserts and accessories the machine comes fitted with to hold, guide, and push oversized stock as well as narrow board ad small workpieces.

Table saws boast versatile functionality and will come in handy for both simple routing cutting jobs and for making some more sophisticated cuts and completing rather tricky cutting tasks. The end results will greatly depend on your skills as well as on backup tools and accessories you use to have the job done. Below, we’ve summed up some useful tips and techniques for the most popular table saw applications.

Rips cuts are the most common type of cuts you’ll be able to do on a table saw. It’s a type of longitudinal cut usually used to cut hardwoods. Before you start cutting, adjust the blade so that it is about 0.25 inches higher than the woodstock thickness. This will help prevent kickback. Adjust the necessary fence width and install the blade guard. Turn the blade on and start pushing the board through it keeping the board tightly to the fence. When cutting, remember to put your fingers away from the blade. Use a push stick when cutting thing rips and attach an outfeed table for making long rips.

Angled cuts such as cross cuts and miter cuts are widely used in cabinetry, joinery, and flooring. These cuts allow creating perfect seamless angled joints. A table saw will let you make clean and precise angled cuts by using a miter gauge. Adjust the blade the same way you would do for ripping to extrude up to about 0.25 inches above the board that enables smoothly cutting through the thickness of your woodstock. Set up the miter gauge into a special slot on the table and using a 45-degree drafting triangle square the gauge to the saw blade to make right-angle cuts or adjust the gauge to 45 degrees to make accurate miter cuts. While cutting, hold your workpiece against the miter gauge fence. If you need to cross cut some thick workpieces like table legs or some support stands, the trick is to cut halfway from one side and then simply flip the stock over to finish the cut from the other side.

In addition to above mentioned common cuts, a table saw allows making dadoes and rabbets using a set of dado blades for table saws, straightening the board edges using a jointer jig, and making flawless box joints with a special box joint jig at hand.