Basically, soldering is the process of connecting two or more metal items together in order to form a secure joint. In contrast to welding used to connect larger metalwork, soldering is a proper technique for making delicate joints and binding small-size or even tiny items. To make a joint, you will need to put some filler alloy or solder into it that acts like a kind of glue or adhesive. Formerly, all solders were based on lead, however, now, there is a whole variety of lead-free alloys safe both for the human health and for the environment. To be applied as a binding agent, the solder needs to be melted. This is exactly what a soldering iron is used for. Featuring a heated tip, the tool will help you not only liquify the solder but also make an accurate connection with it.

To get a permanent and truly reliable joint, it is essential to know what materials can be soldered together and what cannot be soldered. Initially, soldering is meant for metals and this or that way, all metals can be soldered. Yet, it’s worth saying that metals differ in solderability that is the metal ability to create a soldered connection. Thus, noble metals (gold, silver, tin, cadmium, palladium) are distinguished by an excellent solderability and are often contained in solders. Copper, bronze, brass, nickel, lead, carbon steel, zinc, and low alloy steel feature good to average solderability and are pretty easy to solder. The most difficult to solder metals that will need some pre-plating, pre-tinning, or the use of special solder are aluminum, high alloy steels, stainless steel, cast iron, titanium, and magnesium.

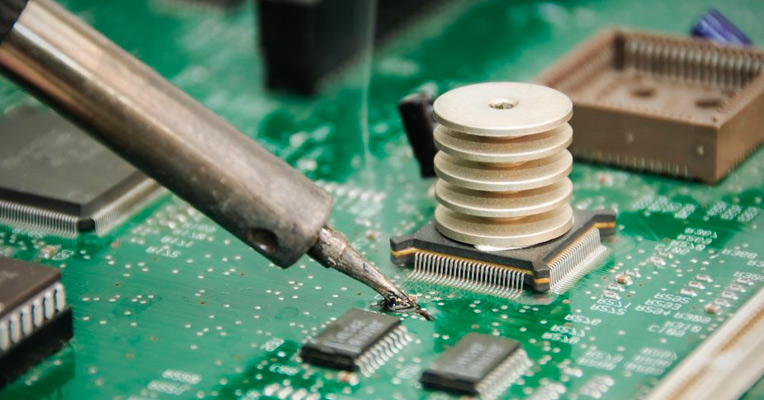

Soldering is most widely used in electronics to connect electrical wires and electronic component, restore poor connections in electrical circuits, on printed circuit boards, repair PCs, terminals, converters, radio devices, and antennas. Yet, the scope of application is not limited only to electronics. Soldering can be applied to join plumbing and refrigeration components, jewelry, machine components, and some mechanical parts as well as to make joints in sheet metal objects.

- Low-heat impact. Since a solder alloy melts at a lower temperature than the adjoining metal, the base item or surface remains almost intact and is in no way damaged by heating.

- Permanent or temporary joints. A soldered joint is solid enough to be a permanent connection, however, since the base metal surface or item is not damaged and does not change its shape or size, the joint can easily be desoldered by simply applying heat and the connected items or parts can be reused.

- Joining different materials. By means of soldering, you can easily connect together metals featuring different melting points. Thus, you can solder brass to aluminum, copper to steel or even connect metals to non-metal materials, such as ceramics.

- Speedy connections. Soldering is a low-temperature technique, which means it won’t take much time for the soldering iron to heat up and melt the solder alloy. Hence, you’ll be able to make multiple connections very quickly.

- Easy to get the hang of. Even if you've never used a soldering iron before great chances are that you will master a soldering technique pretty quickly. There is no need to worry about mistakes you can make until you get the hang of it since the components, items, or parts can easily be re-aligned and re-joined, if necessary.

Seemingly simple, using a soldering iron still requires a certain skill to make precise, smooth, and reliable connections without a hassle. To help you quickly master a soldering technique, we’ve summed up several useful tips on how to use a soldering iron in a proper manner.

- A soldering iron tip becomes extremely hot, to say nothing of the melted metal temperature. Hence, due to a high risk of burns and injuries, you should take care of your personal safety first. Wear special glasses and gloves to protect your eyes ad skin and work in well-ventilated premises to avoid inhaling harmful fumes of melting solders, especially of those based on rosin.

- Before using a soldering iron, make sure it is fully heated up.

- To get a neat and solid joint, it is essential to keep a soldering iron tip clean and free from any solid solder remnants. Clean the tip immediately before the application and continue cleaning it while soldering by simply wiping the tip with a wet sponge.

- Apply a soldering iron tip to the contact area between the components you want to join and hold it for a few seconds. Then, introduce the solder to the joint area and hold it there for another few seconds to let it melt. The amount of solder you need to feed depends on a project at hand and materials you are joining. After removing the solder, hold the tip for another second to form a really good joint and put it away.

- Let the joint cool naturally and do not disturb it to avoid deterioration. A properly soldered joint should look smooth, uniform, and flat without any oxidized stains or grains.

Note: To make perfect wire connections, use wire cutters and wire strippers for cutting the wires and taking off the insulation. Meanwhile, for soldering tiny or close to microscopic details, it is recommended to use a magnifying glass to improve the visibility.

Intermittently heating up and cooling down, a soldering gun or soldering iron tip gets covered with oxides and flux resides, all of this greatly reducing the heat transfer and accelerating the tip wear. To maintain a high heating performance of the tool and prolong its service life to the maximum, regularly tinning a solder iron is a must. Tinning is removing the old solder and debris from the heated tip by simply using a wet sponge to have a nice clean and shiny tip ready for the soldering job at hand.